Accurate pipetting is one of the simplest ways to protect the quality of your data. When a pipette is calibrated and maintained well, your dilutions behave predictably, your assays are easier to reproduce, and your team spends less time repeating runs. The encouraging part is that precision is very achievable: routine Pipette Calibration plus smart maintenance habits can keep most instruments performing beautifully for years.

This guide explains what Pipette Calibration and Repair involves, when you should consider Pipette Repair, how to choose a reliable Pipette Calibration Service, and what to expect from a professional pipette repair service. We’ll also cover where positive-displacement pipettes fit in and why some labs use them to improve accuracy with viscous, volatile, or high-density liquids.

What pipette calibration means

Pipette Calibration is the process of verifying and adjusting pipette performance so it dispenses the intended volume within defined accuracy and precision limits. In practical lab terms, calibration confirms that “100 µL” on the dial truly dispenses 100 µL—consistently. Calibration is typically performed by gravimetric testing (weighing dispensed water under controlled conditions and converting mass to volume). Results are compared against acceptance criteria such as manufacturer specifications or lab-defined QC standards. A great calibration report gives you confidence in your numbers and supports audit readiness for regulated workflows.

Why calibration matters for daily lab work

Even minor volume errors can compound quickly.

- A 2–3% deviation can shift standard curves, alter qPCR efficiency, skew ELISA signal separation, or change enzyme kinetics.

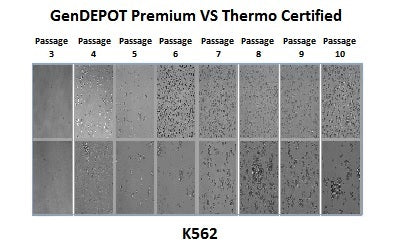

- In cell culture, volume drift can affect reagent concentrations and cell responses.

- In diagnostics and QC, calibration is often a compliance requirement.

The result of consistent calibration is positive: cleaner data, fewer repeats, smoother troubleshooting, and more consistent outcomes between operators.

Signs your pipette needs calibration or repair

Many labs schedule calibration routinely, but it’s also smart to watch for performance cues. If replicate volumes feel inconsistent, assays show unexpected variability, or pipette operation seems rough such as sticky plungers, slow return, misaligned tip ejectors, or minor leakage these are signs your pipette may benefit from attention. Regular calibration, combined with targeted Pipette Repair, is a fast and effective way to restore smooth, reliable performance and maintain assay precision.

Pipette Calibration Service: what’s included

A professional Pipette Calibration Service usually includes:

- Incoming inspection and basic function check.

- Performance testing across specified volumes (often at least 3 points within the range).

- Adjustment to meet the specification when needed.

- Documentation and a calibration certificate/report.

- Labeling with calibration date and due date.

- Optional cleaning, preventive maintenance, and replacement of standard wear parts.

A good service also offers a clear turnaround timeline and a recordkeeping system, so your team can track assets easily.

Pipette Calibration and Repair: What repairs typically involve

Not every issue requires major repair. Many performance problems are caused by small wear parts that are designed to be replaced.

Every day, Pipette Repair items include:

- Seal and O-ring replacement.

- Piston cleaning or replacement.

- Lubrication with appropriate materials.

- Tip ejector alignment or replacement.

- Spring replacement.

- Deep cleaning after sample ingress.

After repair, calibration verifies the improvement, so you leave with a pipette that is both mechanically sound and volume-accurate.

How often should you calibrate pipettes?

- Frequency depends on use, risk, and regulatory requirements.

- High-use pipettes in core labs or production workflows are often calibrated more frequently.

- Pipettes used for critical assays, regulated QC, or clinical workflows often follow stricter schedules.

- Lower-use research pipettes may use a longer interval, paired with quick in-house performance checks.

A practical approach is to start with a standard schedule (for example, quarterly or semi-annual, depending on intensity), then adjust based on your historical performance data.

In-house checks vs external service

- Many labs do quick in-house checks between calibration cycles.

- A simple approach includes gravimetric spot checks at key volumes and documenting results.

- This does not replace a complete calibration program, but it can quickly flag drift and protect critical runs.

- External calibration services are especially valuable when you need traceable documentation, consistent environmental controls, and standardized reporting.

Choosing a pipette repair service: a simple selection guide

When selecting a pipette repair service, look for:

- Clear traceability and documentation practices.

- Defined acceptance criteria (manufacturer spec or your lab SOP).

- Technician expertise across your pipette brands and models.

- Access to genuine or high-quality replacement parts.

- A transparent quote process and repair authorization workflow.

- Intense labeling and asset tracking options.

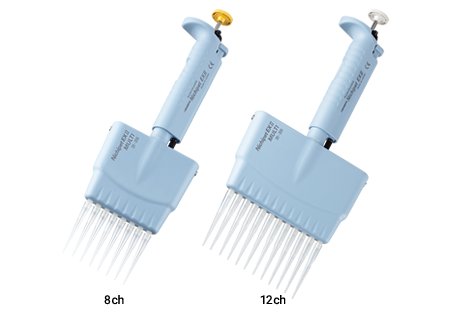

- Support for multi-channel pipettes and specialty models.

If your lab runs audits or quality programs, consistent reporting and traceability are often the most valuable features. Astor Scientific supports lab reliability by helping teams source dependable lab supplies and workflow essentials, making it easier to maintain consistent technique across assays and operators.

Positive displacement pipettes: when they’re the best choice.

Positive displacement pipettes use a piston that directly contacts the sample (often via a disposable capillary/piston assembly). This design reduces errors caused by air cushion effects, which can be a significant advantage for certain liquid types.

They are invaluable for:

- Viscous liquids.

- Volatile solvents.

- Foaming solutions.

- High-density samples.

- Small volumes where evaporation matters.

If your lab frequently works with these liquid classes, positive displacement models can improve accuracy and reduce variability—especially in assays where tight precision makes analysis smoother. Positive displacement pipettes still benefit from regular calibration, and using the correct consumables for the system helps keep performance consistent.

Best practices that keep pipettes accurate longer

- Good habits reduce wear and protect accuracy.

- Use the correct pipette for the volume range; avoid living at the extreme top or bottom.

- Pre-wet tips for better accuracy.

- Use consistent technique: angle, immersion depth, aspiration/dispense speed.

- Avoid laying pipettes down with liquid in the tip.

- Store pipettes on a stand.

- Clean and decontaminate appropriately for your samples.

- Use quality tips that fit well and seal consistently.

These habits make Pipette Calibration more predictable and help reduce the frequency of repairs.

FAQ

What is pipette calibration?

Pipette Calibration is verifying and adjusting pipette performance so dispensed volumes meet accuracy and precision expectations. It provides confidence in results and supports compliance needs.

What is included in a Pipette Calibration Service?

A typical Pipette Calibration Service includes inspection, performance testing, adjustments if needed, and a calibration certificate/report. Many services also offer preventive maintenance.

When do I need pipette repair?

Consider Pipette Repair if you notice leaks, inconsistent volumes, sticky plungers, or if a pipette has been dropped or had sample ingress. Repair plus calibration restores performance quickly.

How often should pipettes be calibrated?

It depends on use and risk. Many labs calibrate more frequently for high-use or regulated workflows, and less frequently for low-use research instruments, supported by periodic in-house checks.

Are positive displacement pipettes more accurate?

They can be more accurate for viscous or volatile liquids because they reduce air cushion effects. For standard aqueous samples, air-displacement pipettes perform very well when the technique and calibration are solid.

Conclusion

A strong calibration program is one of the simplest ways to improve lab consistency. With routine Pipette Calibration, timely Pipette Repair, and a reliable Pipette Calibration Service, your team can keep pipettes performing accurately and confidently across day-to-day experiments. If you’re strengthening your lab workflow, Astor Scientific can support you with dependable consumables and lab essentials that help teams maintain consistent pipetting performance and smoother assay outcomes.