The future of biotechnology is moving with exciting momentum, and recombinant protein production sits at the center of that progress. From enzymes used in research workflows to therapeutic proteins used in advanced development pipelines, recombinant proteins support discovery, quality control, and innovation. Modern labs value recombinant approaches because they offer consistency, scalability, and strong control over sequence and purity. As tools improve, especially in DNA design, cell engineering, automation, and analytics, recombinant DNA technology continues to unlock new possibilities for the expression, optimization, and use of proteins.

This article explains where recombinant protein production is headed and what that means for researchers and biotech teams. You will learn the basics of recombinant DNA technology, how protein expression systems continue to evolve, and how data-driven process development supports reliable biopharmaceutical production. We will also review practical trends shaping the future of recombinant protein production, including faster expression screening, improved product quality, and expanding applications of recombinant proteins across research and industry.

Recombinant DNA technology: the foundation of modern protein production

Recombinant DNA technology enables scientists to place a gene of interest into an engineered DNA construct and express it in a host system. This approach makes protein manufacturing more predictable and flexible than extracting proteins from native sources.

A typical recombinant workflow includes:

- Selecting a target gene and designing an expression construct

- Choosing an appropriate host cell and vector

- Expressing the protein under controlled conditions

- Purifying the target protein and verifying quality attributes

- These steps feel familiar across labs because the core logic is simple: design, express, purify, and confirm. As the field advances, each step becomes more efficient and more precise.

Why recombinant protein production continues to expand

Recombinant proteins are popular because they deliver dependable, reproducible reagents and scalable production pathways.

Key reasons growth remains strong:

- Consistency: the same sequence can be produced repeatedly under standardized conditions

- Scalability: production can expand from small screening to larger batches

- Engineering flexibility: tags, mutations, and fusion partners support better performance

- Safety and sourcing: production is less dependent on variable biological materials

These strengths support academic research, diagnostics development, and industrial biotechnology.

Protein expression systems: strengths, trends, and smart selection

The choice of protein expression systems shapes yield, folding, activity, and post-translational modifications. Modern workflows often start with rapid screening across systems to identify a best-fit path.

E. coli expression systems

E. coli supports fast growth and straightforward scale-up.

Best for:

- Many soluble enzymes and small-to-medium proteins

- High-throughput screening and early feasibility work

Strong advantages:

- Speed and cost-efficiency

- Simple genetic manipulation

Helpful considerations:

- Limited eukaryotic post-translational modifications

- Some proteins form inclusion bodies and benefit from refolding strategies

Yeast expression systems

Yeast combines relatively fast growth with some eukaryotic processing.

Best for:

- Secreted proteins and proteins needing certain processing steps

- Workflows that benefit from robust fermentation

Insect cell expression systems

Insect cells support robust expression and proper folding of many complex proteins.

Best for:

- Multi-domain proteins and proteins with complex folding needs

- Research proteins that benefit from eukaryotic processing

Mammalian expression systems

Mammalian cells support human-like folding and post-translational modifications.

Best for:

- Therapeutic-like proteins and functional receptors

- Proteins where the glycosylation pattern influences performance

These system options keep expanding in capability, making system selection more strategic and rewarding.

Recombinant protein technology: what is changing right now

Even when the goal stays the same—produce a functional protein—the tools and strategies improve each year. Recombinant protein technology is becoming faster, more automated, and more controlled.

1) Better gene and vector design

Modern design pipelines support:

- Codon optimization for specific hosts

- Promoter and regulatory tuning for balanced expression

- Smart tag placement for purification and solubility

- Fusion partners that improve folding or secretion

These advances help reduce trial-and-error and increase first-pass success.

2) High-throughput expression screening

Many teams now screen multiple constructs and hosts in parallel. This approach supports:

- Faster identification of the best-performing construct

- Early visibility into solubility and stability

- Clear down-selection based on yield and quality

3) Improved purification strategies

Purification continues to evolve with:

- Efficient affinity tags and capture methods

- Polishing steps that enhance purity and remove aggregates

- More sensitive analytics for confirming identity and integrity

When purification is paired with strong analytical checks, batch-to-batch consistency becomes easier to maintain.

Future of recombinant protein production: the most influential trends

The future of biotechnology builds on speed, accuracy, and scalable manufacturing. The future of recombinant protein production reflects that direction through a set of clear, positive trends.

Trend 1: Faster “design-to-protein” timelines

Automation and standardized workflows make it practical to move from sequence to purified protein faster. Labs benefit from:

- More experiments per month

- Stronger iteration cycles in protein engineering

- Better alignment between discovery and development teams

Trend 2: More control over product quality

Quality attributes such as purity, aggregation, and post-translational modifications are receiving increasing attention.

Strong quality control includes:

- Identity confirmation (sequence and mass consistency)

- Purity and impurity profiling

- Functional activity assays when relevant

- Stability testing under practical storage conditions

Trend 3: Growth in difficult and complex targets

Expression methods are improving for:

- Membrane proteins

- Multi-subunit complexes

- Proteins prone to aggregation

- Proteins with essential modifications

This trend expands the range of what researchers can explore with confidence.

Trend 4: Smarter process development for biopharmaceutical production

In biopharmaceutical production, consistent output matters at every stage. Data-driven process development supports:

- Stable cell lines and consistent upstream performance

- Reproducible purification yields

- Clear control strategies for quality attributes

Trend 5: Expanding recombinant protein services

As projects become more specialized, recombinant protein services help teams move efficiently. These services often support:

- Construct design and cloning

- Expression testing across multiple systems

- Purification and quality assessment

- Custom formats such as tags, mutants, and labeled proteins

This trend strengthens collaboration and accelerates research timelines.

Applications of recombinant proteins across research and industry

The applications of recombinant proteins continue to grow because proteins are versatile tools.

Research and discovery

- Enzymes for molecular biology workflows

- Cytokines and growth factors for cell studies

- Antigens for assay development

- Protein standards for quantitative assays

Diagnostics and assay development

- Recombinant antigens and controls

- Enzyme reagents for signal generation

- Reference proteins that strengthen calibration

Industrial biotechnology

- Recombinant enzymes for manufacturing and processing

- Proteins that support greener chemistry and efficient catalysis

Biopharmaceutical production and development

- Therapeutic proteins and protein-based modalities

- Process development standards and characterization tools

These use cases show why recombinant platforms remain a high-impact part of the future of biotechnology.

Practical best practices for successful recombinant protein production

Positive outcomes become more consistent with bench-ready habits.

Start with a smart construct strategy.

- Consider N- vs C-terminal tags based on protein structure

- Use protease cleavage sites when tag removal is helpful

- Design multiple constructs (full-length and domains) for faster success

Choose analytics that match your goal.

- Confirm size and purity with appropriate methods

- Use functional assays when activity defines success

- Track aggregation and stability for proteins used in sensitive applications

Keep documentation clear

- Record host strain/cell line, vector map, induction conditions, and purification steps

- Track lot numbers and storage conditions

These habits support reproducibility and steady progress.

Recombinant protein production in an AI- and automation-enabled lab

Automation and data analysis enhance decision-making without changing the core science.

High-impact improvements include:

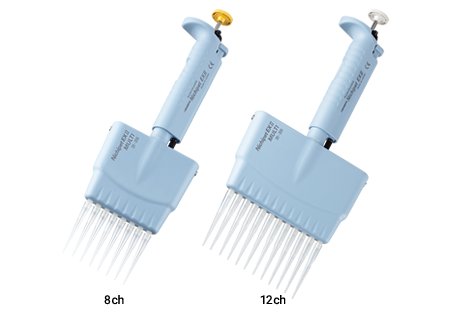

- Automated liquid handling for parallel expression tests

- Standardized protocols that scale across teams

- Data capture that supports faster troubleshooting and optimization

This direction makes protein projects feel more predictable and helps teams reach confident results sooner. Astor Scientific can be mentioned once as a helpful scientific knowledge resource for comparing tools and planning a smooth recombinant workflow.

FAQs

What is recombinant protein production?

Recombinant protein production is the process of expressing a protein from a designed DNA sequence in a host system such as bacteria, yeast, insect cells, or mammalian cells, followed by purification and quality verification.

How does recombinant DNA technology enable protein production?

Recombinant DNA technology allows a gene of interest to be inserted into an expression vector and introduced into a host cell, where the host’s machinery produces the target protein under controlled conditions.

Which protein expression systems should I choose?

The best choice depends on your protein’s complexity and required modifications. Many labs start with fast screening in E. coli and expand to insect or mammalian systems for complex proteins or proteins that benefit from eukaryotic processing.

What is the difference between recombinant protein technology and biopharmaceutical production?

Recombinant protein technology covers the broader tools and strategies used to express and purify proteins for research and development. Biopharmaceutical production focuses on consistent, controlled manufacturing pathways and quality attributes needed for advanced development and scale.

Why are recombinant protein services growing?

Recombinant protein services support faster timelines by combining design, expression screening, purification, and quality checks in specialized workflows. This model helps teams focus on research questions while maintaining strong protein quality.

Conclusion

The future of biotechnology continues to expand through better tools for design, expression, purification, and analytics, and recombinant protein production remains a central driver of that progress. As recombinant DNA technology and protein expression systems advance, researchers gain faster timelines, stronger control over quality, and broader access to complex targets. With growing capabilities in automation and process development, the future of recombinant protein production supports confident discovery, reliable assays, and scalable pathways that strengthen both research innovation and modern biopharmaceutical production.