Even well-designed assays can have “off days,” especially when you’re working with complex samples, tight detection limits, or multiple operators. The good news is that most ELISA Problems follow recognizable patterns—and once you know what to look for, the fixes are usually straightforward. With a few consistent checks, you can turn inconsistent plates into stable, repeatable runs. This guide is a practical ELISA assay troubleshooting resource built for day-to-day lab work. You’ll learn the most common issues seen in an ELISA assay, the most reliable ELISA Solutions for each, and how to use strong ELISA controls to confirm you’re truly back on track. We’ll also cover how plate choice and handling on a Microtiter plate can influence background, variability, and curve quality.

A quick mindset that makes troubleshooting faster

The easiest way to debug an ELISA is to treat it like a system with a few significant “levers.” Almost every issue can be traced to one of these areas.

- Reagents and antibodies: concentration, stability, storage, expiration.

- Timing and temperature: incubation length, room temperature swings, plate sealing.

- Washing and aspiration: residual volume, consistency, soak time.

- Plate and surface effects: binding capacity, coating uniformity, edge effects.

- Pipetting and mixing: accuracy, bubbles, consistent technique.

- Sample matrix: serum/plasma interference, hemolysis, lipids, detergent carryover.

When you adjust one lever at a time and keep your controls strong, results improve quickly and predictably.

Start here: confirm your ELISA controls.

Before changing the protocol, confirm your controls. Strong ELISA controls tell you whether the problem is chemistry, technique, or sample-related. A reasonable control set usually includes a blank well, a zero standard (matrix without analyte), a mid-range standard, and a positive control sample that you know should land in range. If your kit includes recommended controls, follow them first. For custom assays, build a simple, repeatable control panel and keep it consistent between runs.

Common ELISA Problems and their most reliable ELISA Solutions

1) High background across the plate

High background is one of the most common ELISA Problems, and it is also one of the most fixable. Common causes include incomplete washing, wells drying between steps, overly concentrated detection reagents, insufficient blocking, or contamination.

Positive, practical ELISA Solutions include adding one wash cycle, including a short soak step, confirming wash buffer composition, improving blocking, and ensuring smooth transitions between steps so wells stay comfortably wet. If the background is uniform and high, the fix is often in washing, blocking, or reagent concentration rather than in the plate itself.

2) Weak signal or low OD values

A low signal can feel frustrating, but it usually points to a small number of easy checks. Common causes include incorrect reagent preparation, under-incubation, over-washing for that specific assay, enzyme/substrate issues, or degraded standards.

Strong ELISA Solutions include confirming dilution calculations, ensuring proper incubation time and temperature, verifying substrate is fresh and protected from light, and checking that antibodies and conjugates have been stored correctly. If you’re close to the expected range, minor improvements—like slightly more prolonged incubation or optimizing antibody concentration—often bring signal into a comfortable window.

3) High variability between replicates

When replicates don’t agree, the good news is that consistency improvements are usually quick. Common causes include inconsistent pipetting, bubbles, insufficient mixing, the plate not being tapped down after dispensing, and uneven washing or aspiration.

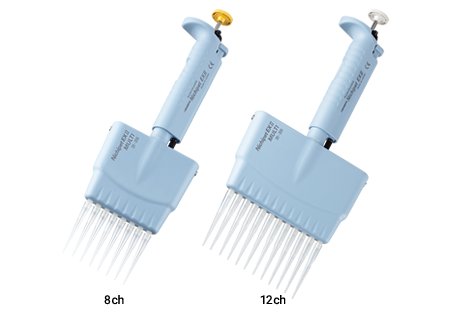

Solutions include using calibrated pipettes, pre-wetting tips, consistent pipetting rhythm, mixing standards and samples gently but thoroughly, avoiding bubbles, and using an automated washer when plate volume rises. A simple practice that helps: dispense into the same position in each well and keep timing consistent across the plate.

4) Edge effects (outer wells behave differently)

Edge effects are typical on a Microtiter plate because outer wells may experience faster temperature changes or evaporation. Consistent incubation conditions and timely handling help maintain uniform hydration across the plate and support reliable results.

Solutions include using plate sealers during incubations, keeping plates away from vents or direct airflow, and incubating on a stable surface. Many teams also avoid using edge wells for standards in sensitive assays, which can improve curve stability. With a couple of environmental tweaks, edge effects often disappear.

5) Nonlinear standard curve or poor curve fit

A curve that doesn’t behave can still be a positive sign: it usually means one step needs alignment. Common causes include incorrect standard dilutions, poor mixing during serial dilution, pipetting errors, plate reader issues, or concentrations outside the assay’s working range.

Solutions include remaking the standard curve with careful mixing at each step, using fresh standards, verifying plate reader settings, and ensuring you are fitting the curve with the recommended model. If samples fall outside the curve, a simple dilution or concentration adjustment puts them into the curve’s sweet spot.

6) Unexpectedly high signal in negatives

When negatives look high, it often comes down to nonspecific binding or contamination. Causes include insufficient blocking, cross-reactive antibodies, carryover from pipette tips, or plate handling that allows splashing.

Solutions include optimizing blocking, using fresh tips between wells, avoiding touching the sound walls with tips, and confirming wash steps entirely remove residual liquid. If your assay uses secondary antibodies, confirm that the secondary is compatible and not binding to sample components.

7) Signal saturation (top standards plateau early)

Saturation is a regular part of assay physics, and it can be managed easily. Causes include very high analyte levels, too-strong detection reagents, or plate binding limits.

Solutions include diluting samples, reducing detection antibody concentration slightly, and ensuring standards bracket the sample range. When you keep most samples in the curve’s mid-range, quantification becomes smooth and consistent.

8) Day-to-day plate drift

If results shift between days, you’re usually close to stability—drift often means one workflow variable isn’t entirely standardized. Causes include temperature differences, incubation timing differences, reagent stability, or minor changes in wash performance. Solutions include using timers for every incubation, standardizing room temperature conditions when possible, using the same plate shaker settings, and keeping reagents equilibrated to the right temperature before use. Running the same positive control sample each day is a simple way to confirm your assay is behaving consistently.

ELISA assay troubleshooting checklist

- If you want a fast reset, this checklist often resolves most problems in one pass.

- Confirm your ELISA controls: blank, zero, mid-standard, and positive control.

- Verify standards: correct dilutions, thorough mixing, and fresh preparation.

- Check wash quality: complete aspiration, no residual droplets, optional short soak.

- Prevent drying: smooth transitions and plate sealers.

- Confirm reagents: correct storage, expiration, and light protection for substrate.

- Review pipetting: calibration, consistent timing, bubble-free dispensing.

- Check plate reader settings: wavelength, integration time, and blank subtraction.

- Adjust sample prep: dilution, matrix matching, and avoiding freeze-thaw cycles.

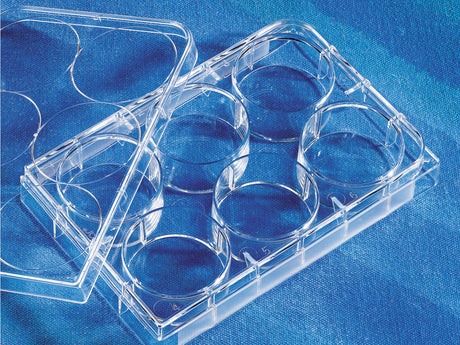

How the microtiter plate choice affects results

Not all plates behave the same way, even when they look identical. A high-binding Microtiter plate can improve sensitivity for some targets, while a medium-binding surface may reduce nonspecific binding in other workflows. If you switch plates, confirm that coating conditions (for capture assays), blocking, and washer settings still produce clean aspiration and a stable background. Astor Scientific supports labs that want consistent ELISA performance by helping teams source dependable microplates, buffers, and workflow essentials so protocols remain stable across projects and operators.

ELISA controls: how to build confidence in your numbers

Strong ELISA controls do more than “check a box.” They make your troubleshooting faster and your data easier to defend.

- A practical approach is to keep a frozen aliquot of a positive control sample (when appropriate for your analyte) and run it with every plate.

- Use duplicates or triplicates for standards.

- Include a no-sample blank to measure the baseline.

- If matrix effects are expected, run matrix-matched standards or perform dilution linearity checks.

When controls behave, it is much easier to interpret fundamental biological changes in your samples.

FAQ

What are the most common ELISA Problems?

Background, signal strength, replicate consistency, edge uniformity, and standard curve performance are all areas that can be readily optimized to improve assay quality.The encouraging part is that each has a short list of reliable fixes.

What are the best ELISA Solutions when my background is high?

Add a wash cycle, include a brief soak, confirm aspiration is complete, optimize blocking, and avoid drying between steps. These steps often reduce the background quickly.

How do I approach ELISA assay troubleshooting without changing everything?

Change one variable at a time, keep your controls constant, and document the results. This approach makes improvements clear and prevents accidental “over-optimization.”

Why does my ELISA assay have edge effects?

Outer wells can experience more evaporation or faster temperature change. Plate sealers, stable incubation conditions, and smoother timing reduce edge effects significantly.

Do I need specific ELISA controls for every plate?

Yes, controls make your run interpretable. A blank, standards, and a positive control sample are a strong foundation.

Conclusion

Most ELISA issues are not failures—they are signals that one part of the workflow needs a minor tune-up. When you confirm your ELISA controls, standardize washing and timing, and keep samples within the curve’s working range, you can resolve ELISA Problems quickly and produce reliable, repeatable results. If you’re upgrading your ELISA workflow, Astor Scientific can support you with lab-ready consumables and dependable microplate essentials that help your team run smoother assays and generate confident data day after day.