CHO cells, short for Chinese hamster ovary cells, are one of the most widely used cell lines in modern biotechnology. Since their introduction in the 1960s, they have played a critical role in the development of therapeutic proteins, vaccines, and cutting-edge medical research. Their adaptability, stability, and ability to produce human-compatible proteins make them a preferred choice for both academic and industrial laboratories.

Unlike other immortalized cells, CHO cells can be grown in suspension or adherent cultures, making them versatile for different experimental setups. They also have a proven safety record, which is vital in the pharmaceutical industry. Today, they are the backbone of many FDA-approved biologics and a reliable platform for scaling up production.

What Are CHO Cells?

CHO cells originate from the ovary tissue of the Chinese hamster (Cricetulus griseus). These cells have been adapted to grow indefinitely in laboratory conditions, meaning they can divide continuously without undergoing normal cell aging or death. This characteristic places them in the category of immortalized cells, allowing researchers to maintain consistent results over extended periods.

Their genetic stability, coupled with a high tolerance for genetic modification, makes them ideal for recombinant DNA technology. Through this approach, scientists can insert specific genes into CHO cells, instructing them to produce complex proteins that closely mimic human versions. This is particularly valuable in producing monoclonal antibodies, clotting factors, and enzymes used in treatments for chronic diseases.

History and Significance in Biotechnology

The use of CHO cells began in the early 1960s, but they rose to prominence in the 1980s with the commercial production of recombinant proteins. One of the first major breakthroughs was the production of recombinant human tissue plasminogen activator (rtPA), a drug used to dissolve blood clots. This success demonstrated the potential of CHO cell lines as a safe and efficient production system, leading to their widespread adoption.

Today, CHO cells are responsible for manufacturing the majority of therapeutic proteins on the market. Their ability to perform human-like post-translational modifications, such as glycosylation, ensures that the proteins they produce are biologically active and compatible with human patients.

Why Are CHO Cells Preferred?

While there are many cell lines available, CHO cells stand out due to their scalability, safety, and adaptability.

Genetic Flexibility

CHO cell lines can be easily engineered to produce different proteins. Researchers can customize them to increase yield, enhance stability, or alter protein structure for better therapeutic performance.

Growth in Serum-Free Media

Modern CHO cell lines can thrive in serum-free media, reducing the risk of contamination from animal-derived products. This makes them safer for pharmaceutical applications and aligns with regulatory guidelines.

Robustness in Large-Scale Production

CHO cells can grow in suspension cultures, enabling them to be used in bioreactors for mass production. Their ability to maintain productivity even under stress makes them cost-effective for large-scale manufacturing.

Common CHO Cell Lines

Several CHO cell line variants have been developed to meet specific production needs.

- CHO-K1: Widely used for research and protein production due to its stable growth and adaptability.

- CHO-S: Adapted for suspension growth, making it ideal for large-scale bioreactors.

- CHO-DG44: Lacks dihydrofolate reductase (DHFR), allowing for gene amplification strategies to boost protein yield.

Each variant offers unique advantages, and the choice depends on the protein being produced and the desired manufacturing process.

Applications of CHO Cells

CHO cells have become one of the most widely used systems in biotechnology due to their ability to produce complex, human-compatible proteins at large scale. Their adaptability, stability, and capability to perform human-like post-translational modifications make them ideal for pharmaceutical research and manufacturing. Over the years, these cells have moved from being just a laboratory tool to becoming the foundation of modern biotherapeutic production.

Biopharmaceutical Production

The most significant application of the CHO cell line is in the large-scale production of therapeutic proteins, including monoclonal antibodies, hormones, and enzymes. Since they can fold proteins correctly and add appropriate sugar molecules, Chinese hamster ovary cells help create biopharmaceuticals that are safe, effective, and less likely to cause immune reactions in patients. Many of the world’s top-selling drugs, such as treatments for cancer and autoimmune diseases, are manufactured using CHO-based systems.

Vaccine Development

Immortalized cells like CHO are valuable in vaccine research and production. They are often used to produce recombinant antigens or viral vectors that form the basis of modern vaccines. Their consistent growth and ability to be engineered make them ideal for producing large batches of high-quality vaccine components, ensuring scalability for global immunization programs.

Protein Engineering & Research

CHO cells serve as an essential platform for scientists working on protein engineering. By modifying the genetic code within these cells, researchers can create custom proteins with enhanced stability, functionality, or therapeutic activity. This application is critical in the development of new drug candidates, enzyme therapies, and diagnostic tools.

Biosimilar Development

As patents for original biologics expire, CHO cell lines are increasingly being used to produce biosimilars, highly similar versions of existing biopharmaceuticals. This not only helps reduce costs for patients and healthcare providers but also ensures consistent product quality, thanks to the reproducible growth characteristics of CHO cells.

Advanced Gene Therapy Research

CHO cells are also being investigated as potential vectors for delivering therapeutic genes. Their compatibility with genetic engineering makes them suitable for creating viral and non-viral delivery systems in experimental gene therapy applications.

Advantages of CHO Cells in Biopharmaceutical Production

The CHO cell line has become the gold standard for biopharmaceutical manufacturing due to its remarkable adaptability and productivity. Unlike many other cell systems, Chinese hamster ovary cells grow well in suspension cultures, making them ideal for large-scale production in bioreactors. They can thrive in serum-free and chemically defined media, reducing the risk of contamination and simplifying downstream purification processes.

Another key advantage is their post-translational modification capability, particularly human-like glycosylation. This feature is critical when producing complex therapeutic proteins such as monoclonal antibodies, where proper glycosylation impacts stability, activity, and safety. Moreover, CHO cells are robust and resilient to environmental stress, ensuring consistent yields over long production cycles.

The use of immortalized cells like CHO also means they can be cultured indefinitely, providing a stable, reproducible platform for biopharma companies worldwide. With decades of optimization and regulatory familiarity, CHO-based production systems remain the industry’s trusted choice for safe, scalable, and high-quality biologics manufacturing.

Genetic Engineering in CHO Cells

One of the main reasons CHO cells remain indispensable is their genetic flexibility. Scientists can introduce specific genes into the CHO cell line to produce a target protein or modify existing genes to enhance productivity. Advanced techniques such as CRISPR-Cas9, site-specific integration, and vector optimization have made it possible to create highly efficient clones with predictable performance.

Stable vs. Transient Expression Systems

- Stable expression in CHO cells ensures long-term protein production through integration of the gene into the host genome. This is ideal for commercial manufacturing where consistency is key.

- Transient expression allows for rapid protein generation without permanent integration. It’s often used in early-stage research or for producing small batches of experimental proteins.

By mastering both systems, researchers can tailor CHO-based workflows to match project timelines and cost-efficiency goals.

CHO Cells in Therapeutic Antibody Production

Therapeutic antibodies represent one of the largest markets for biologics, and Chinese hamster ovary cells dominate their production. This preference is due to CHO cells’ ability to produce antibodies with human-compatible glycosylation, ensuring safety and effectiveness. Monoclonal antibodies, bispecific antibodies, and antibody-drug conjugates are all successfully manufactured using CHO-based systems.

In addition, CHO cells support the production of fusion proteins and recombinant enzymes, further expanding their utility in modern medicine. Many blockbuster drugs, including several for cancer and autoimmune diseases, rely entirely on CHO cell line manufacturing.

Role in Vaccine Development

Beyond therapeutic proteins, CHO cells have been instrumental in vaccine research and production. They can be engineered to express viral proteins, forming the basis for subunit vaccines. During the COVID-19 pandemic, CHO cells played a role in producing recombinant spike proteins for vaccine candidates. Their scalability, safety profile, and ability to generate high yields made them an attractive choice for rapid deployment in emergency situations.

Continuous Manufacturing with CHO Cells

The pharmaceutical industry is increasingly shifting toward continuous manufacturing to meet rising global demands and reduce costs. CHO cells adapt well to perfusion-based systems, where fresh media are continuously supplied, and products are harvested without stopping the culture. This approach not only boosts productivity but also improves product quality consistency.

As regulatory agencies embrace continuous production methods, CHO-based systems are set to become even more important in the future of biopharma manufacturing.

Emerging Applications and Future Outlook

CHO cells are now being used in innovative fields such as gene therapy and regenerative medicine. Their adaptability makes them a candidate for producing viral vectors, growth factors, and specialized proteins needed in advanced therapeutic approaches. With ongoing genetic enhancements and bioprocess improvements, the CHO cell line is expected to maintain its dominance while opening doors to new applications in precision medicine.

In the coming years, advancements in synthetic biology and artificial intelligence-driven process optimization will likely make CHO-based systems even more efficient, further solidifying their role in delivering life-saving therapies worldwide.

Advanced Applications & Research with CHO Cells

Biopharmaceutical Production

One of the most valuable uses of CHO cells is in large-scale biopharmaceutical manufacturing. Their ability to produce complex glycoproteins makes them an essential choice for creating therapeutic proteins like clotting factors, enzymes, and growth hormones. Because CHO cells can perform human-like post-translational modifications, the resulting drugs are both effective and safe for clinical use. The pharmaceutical industry invests heavily in optimizing CHO cell culture processes to increase yields while maintaining product quality.

Vaccine Development

CHO cell lines are a preferred system for producing recombinant subunit vaccines. They provide a safe and controlled environment for generating antigens without the risk of introducing live pathogens. This technology has been applied to vaccines for diseases like influenza, hepatitis B, and more recently, experimental vaccines for emerging viral threats. The adaptability of CHO cells to different expression systems makes them an attractive platform for both established and novel vaccines.

Protein Engineering & Optimization

Researchers frequently use CHO cells for protein engineering studies, aiming to improve the stability, activity, and therapeutic potential of recombinant proteins. By modifying gene sequences and culture conditions, scientists can enhance protein folding, reduce degradation, and fine-tune glycosylation profiles. This precise control over protein characteristics allows for the development of more effective and targeted treatments for various diseases.

Gene Therapy Vectors

CHO cells are also valuable in producing viral vectors for gene therapy. Their scalability and ability to grow in suspension cultures make them suitable for high-volume manufacturing. Using CHO cells, scientists can produce viral particles with consistent quality and safety profiles, which is crucial for clinical applications. These vectors are used to deliver therapeutic genes into patients’ cells, offering potential cures for genetic disorders.

CHO Cells in Cutting-Edge Research

Studying Complex Cellular Pathways

CHO cells serve as a model system for studying biochemical pathways such as glycosylation, protein trafficking, and signal transduction. Because they are well-characterized and easy to manipulate genetically, researchers can dissect molecular mechanisms with high precision. These studies often lead to the identification of new drug targets and improved therapeutic strategies.

CRISPR & Genetic Engineering Advances

Recent advancements in CRISPR-Cas9 technology have significantly boosted the potential of CHO cells in research and development. Genetic engineering enables scientists to knock out undesirable genes, insert beneficial traits, and create specialized cell lines tailored for specific production needs. This approach not only enhances protein yield but also reduces impurities in the final product.

Role in Personalized Medicine

As the field of personalized medicine grows, CHO cells are increasingly used to develop therapies tailored to individual patients. By engineering CHO cell lines to produce patient-specific proteins or antibodies, pharmaceutical companies can create treatments that are more effective and have fewer side effects. This individualized approach is expected to play a major role in the future of medicine.

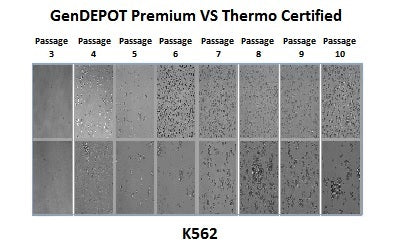

Challenges in Using CHO Cells

While CHO cells offer many advantages, their use in biotechnology and pharmaceutical research is not without challenges. One of the primary issues is the variability between cell lines, which can impact consistency in protein expression and glycosylation patterns. This variability can occur due to genetic drift over time, especially if cells are passaged too frequently. Another concern is the high cost of maintaining CHO cultures, as they require specialized media, controlled environments, and skilled personnel to manage the process effectively. Additionally, producing certain complex proteins may require genetic modifications, which can be time-consuming and resource-intensive. Despite these challenges, advancements in cell line engineering and culture optimization are helping to overcome many of these limitations, making CHO cells even more reliable for large-scale applications.

Future Outlook for CHO Cell Technology

The future of CHO cell technology looks promising, as ongoing research focuses on improving cell line stability, increasing productivity, and enhancing protein quality. Scientists are developing next-generation CHO cell lines with better growth rates and more predictable expression profiles. Automation and artificial intelligence are also being integrated into cell culture processes, allowing for real-time monitoring and optimization. Moreover, gene-editing tools like CRISPR-Cas9 are being used to fine-tune CHO cells for specific production needs, such as reducing unwanted glycosylation patterns or improving resistance to stress conditions. With these innovations, CHO cells are expected to remain the workhorse of the biopharmaceutical industry for decades to come, supporting the creation of more effective therapies and reducing production timelines.

Final Thoughts

CHO cells have transformed modern biotechnology by providing a reliable, adaptable, and scalable platform for producing complex proteins, vaccines, and therapeutic antibodies. Their unique characteristics, such as human-compatible glycosylation, adaptability to various culture conditions, and proven safety profile, make them invaluable to research and industry. While challenges remain, the rapid pace of scientific advancements ensures that these immortalized cells will continue to play a central role in drug development and manufacturing. As demand for biopharmaceuticals grows, CHO cells will remain at the forefront of innovation, helping deliver life-changing treatments to patients worldwide.